|

|

|

|

|

|

|

|||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

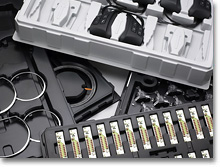

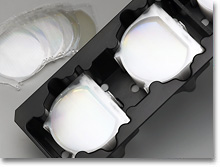

| Individual nest geometry | Thermoformed insert for illuminated indicators | Tray for automatical assembly |

|

|

|

| Workpiece holder systems on a high level exactness concerning outside and inside dimensions |

Great variety of application possibilities for stockable transport- and storage container systems | Exactly formed stack geometry of a component carrier |